My Story

Saturday, January 20, 2007

Last Chapter

Alias, after finding the glorious internet, the 6 apprentices found out that

the internet do have what they were looking for - pieces of the secret manual.

After reading through, they found out that it contains information that taught them

the way of the DCM how material Handling Equipment helps in Material Handling.

Out of nowhere, the manual emitted a bright radiance, the blinding flash enshrouded the

6 apprentices... within seconds all when brilliant white... then...

"OK Class Ended! Remember to prepare for next week's DCM tutorial." Mr Goh said, looking

at the teen head resting on his desk, "WAKE UP! Lesson have already ended!" The blurry eye

teen looked up upon his lecturer and say "where are my 5 other apprentices ????" Mr Goh shake his head and walk away.......

-5:53 PM-

Friday, January 19, 2007

In the view of AS/RS versus Order Picker TruckCons

- High capital investment

- Constantly upgrade the software

- Need regular maintenance

- Require a backup power supply

- Less environmentally friendly in the sense of power consumption compared to OPT

Pros- More efficient (cut down on traveling to and fro)

- ASRS has a faster way to pick goods

- ASRS is fully automated, decreasing cost in the long term

- Retrieval of materials from ASRS can be done using internet access

- ASRS can be upgrade and expand due to the advance technology capabilities

- ASRS is able to work in a very cold environment to a temperature of -20F allowing operators to conduct order picking without stepping into the cold room.

- ASRS tighten security as ID of operators operating the ASRS will be captured in the system, therefore tracking can be done

- Human errors in physical handling can be ELIMINATED

-8:35 PM-

Thursday, January 18, 2007

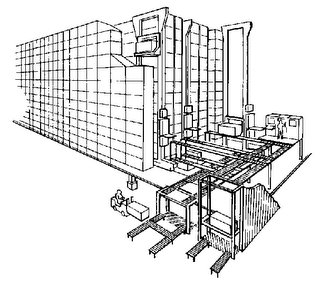

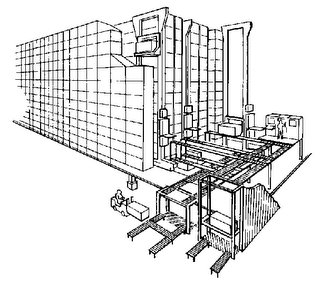

Unit Load AS/RS

Unit Load AS/RS

Used to store/retrieve loads that are palletized or unitized and weigh over 500 lbs.

Stacking heights up to 130 ft. high, with most ranging from 60 to 85 ft. high; 5 to 6 ft. wide aisles; single- or double-deep storage racks.

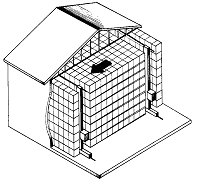

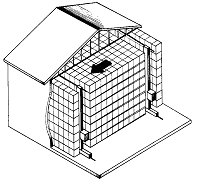

Miniload AS/RS

Miniload AS/RS

Used to store/retrieve small parts and tools that can be stored in a storage bin or drawer

End-of-aisle order picking and replenishment

Stacking heights range from 12 to 20 ft.; bin capacities range from 200 to 750 lbs.

Termed a "microload AS/RS" when used in assembly, kitting, and testing operations to deliver small containers of parts to individual workstations, where workstations are typically located on the sides of a pair of racks.

Man-On-Board AS/RS

Man-On-Board AS/RSUsed for in-aisle picking; operator picks from shelves, bins, or drawers within the storage structure

Manual or automatic control

S/R machine is similar to an order picker or turret truck and can sometimes operate as an industrial truck when outside an aisle, except the S/R is guided along a rail when operating in an aisle

Deep-Lane AS/RS

Deep-Lane AS/RS

Similar to unit load AS/RS, except loads can be stored to greater depths in the storage rack

A rack-entry vehicle is used to carry loads into the racks from the S/R machine, and is controlled by the S/R machine

Termed as an "automated item retrieval system" used to automatically retrieve individual items/cases, with replenishment taking place manually.

-2:39 AM-

Pictures of AS/RS:

-2:07 AM-

AS/RS

Advantages:

- Fewer material handlers

- Better material control (including security)

- More efficient use of storage space (Cubic Utilisation INCREASED)

- Expansion IS ENCOURAGED. (The retrieval system is designed with advanced technological capabilities that can be upgraded and expanded )

- Cost savings. (The retrieval system eliminates the need and cost for offsite storage facilities )

- Lesser occurence of errors

- More time savings

- Allow staff to do other value added jobs meanwhile AS/RS does the picking

Disadvantages:

- High capital and maintenance costs

- Once implement, it will be difficult to modify

-1:56 AM-

Introduction

Besides order picking truck using the help of order picker, there are alternative devices/tools to replace the order picking truck. Advancement in technolo

gy gradually allows storage and picking of inventory to be increasingly streamlined and efficient, resulting in overall lower operational cost and increased performance.

As a result, manual material handling devices, or the MHE (Material Handling equipment), may eventually result being phrase out, paving way for more advance equipment such as the automated guided vehicles (AGVs) or the ASRS.

Automated Storage and Retrieval Systems Consists of an integrated

computer-controlled system that combines the storage medium, transport mechanism, and controls with various levels of

automation for fast and accurate random storage of products and materials.

How AS/RS Works?Storage/retrieval (S/R) machine in an AS/RS operates in narrow aisle, serving rack slots on both sides of aisle; can travel in horizontal (along the aisle) and vertical (up and down a rack) directions at same time.

It works via a robotic "arm" that quite literally fetches materials from archival locations to a pick up locations withour human intervention.

The next post we will be touching on the advantages and disadvantages of using AS/RS. To be continued....

-12:07 AM-

Sunday, January 07, 2007

Power source

There are different types of power source for trucks that needs energy to operate and they are:

- Internal combustion engine – liquefied petroleum gas, petrol

- Compression ignition engine – diesel

- Electric motor

- Battery charged

- Diesel

Mostly, Order picking trucks are battery operated. It might be due to technology and efforts made to conserve the environment to prevent pollution and conserve diesel.

Equipment Maintenance

Wear and tear will eventually happen to the equipment, thus causing either obsolescence, reparation or even replacing part cost to be incurred. Hence, regular inspections and checks should be done at least quarterly to ensure that the equipment are still up to job.

A maintenance programme can be set up. The first step is to identify and locate each piece of equipment by tagging them with a number. A record for each piece of equipment should be present and should keep a record of the amount of fuel consumed, number of hours work, date of maintenance carried out or repairs done. It is best to allocate the same operator to the equipment he uses, so that he will feel that it is his responsibility.

In addition for each piece of equipment, a schedule of maintenance should be prepared for the operator, the regular mechanical inspection and the trained mechanic.

-8:39 PM-

There are many different kinds of material handling equipment such as,

Our group will focus on Order Picking Trucks.

Order Picking Trucks

Basically, order picking trucks are used to pick goods to fulfill orders. For ground level picking, pallet trucks, pedestrian trolleys and roll cage pallets can be use.

Pictures on order picking trucks:

Name: Vertical order picker (EKS110)

Weight limit: 1000kg

Picking limit: 4600mm

Use: Picking of goods from location and taking of pallets. Can be used to pick loose items from different locations in the warehouse.

Compabilites: This Order Picker allows wide big range of load storage units to be raised off ground horizontally and vertically. The auxiliary lift ensures that the picked goods can be stored at an reachable height

Name: Vertical order picker (EKS310)

Weight limit: 1000kg

Picking limit: 10,390mm

Use: Similar to Order picking Truck Model EKS110

Compabilities: This EKS310 can pick goods at a greater height compared to EKS110. Designed to pick single articles from racking and has medium performance segment. It can optimize order picking through an additional lift which increases both flexibility and efficiency. Its design provides maximum movement and flexibility. The high efficiency is available to operator for effortless operation.

Safety:

This order picker will not operate if safety doors are not closed.

The two-piece operating console and large display ensures first class safety and operating comfort

Switch-free sensors pass the information of registered operator’s touch to the onboard computer whereby to ensure all safety relevant checks are carried out.

Name: Horizontal order picker (ECE220)

Weight limit: 2000kg

Height limit: 125mm

Use: Pick at low level of racks in a warehouse

Capabilities: Having powerful acceleration and high end speed; together with same time significant energy saving, prolong the machine life time and cut down on maintenance.

Safety: The purpose of the stand-on platform is to ensure safe and efficient order picking. The availability of the raising stand-on platform makes order picking easier even at second racking level.

-7:51 PM-

Chapter 4History of Material Handling equipment (MHE)

Where it all begins;

Where it all begins;

The Wheel is regarded as one of the most important invention of human civilization

“Originated in ancient Sumer in Mesopotamia (modern Iraq) in the 5th millennium BC, originally in the function of potter's wheels”

Without the wheel, the forklift or any other material handling equipment would be still nothing more than a dream.

Source:

http://en.wikipedia.org/wiki/Wheel Next in line would be the cart, though not entirely an advance version of the MHE, though maybe not even a MHE itself, undoubtedly its basic functionality remains the same, as mention in http://en.wikipedia.org/wiki/Cart , “Carts have many different shapes but the basic idea of transporting material (or maintaining a collection of materials in a portable fashion) remains.”

Next in line would be the cart, though not entirely an advance version of the MHE, though maybe not even a MHE itself, undoubtedly its basic functionality remains the same, as mention in http://en.wikipedia.org/wiki/Cart , “Carts have many different shapes but the basic idea of transporting material (or maintaining a collection of materials in a portable fashion) remains.”

Prior to the invention of the lift truck, the hoist have been widely used to transport heavy loads vertically to a elevated platform.

“Both systems fail over time through fatigue fractures if operated repeatedly at loads more than a small percentage of their tensile breaking strength.”

Perhaps due to its limited durability in operation and safety concerns (cables and chain have been know to snap) eventually lead to the development to……

Sources: www.gmh.co.uk www.mhia.org

The Forklift!

The Forklift!Evolve from the hoist, the fork boast portability

of the MHE, ability to move inventory/goods vertically and horizontally in which its predecessor can’t.

Now, the forklift is able to reach higher and further place due to advanced technology

http://www.ttt-services.co.uk/truck_history.htm

In the near future

Although already widely used, in the future, perhaps the ASRS would outlive the MHE, and perhaps transformed warehouse into a truly stream-less and manpower efficient, for all sorts of products, regardless of size

Source: http://www.fatainc.com/product_automated_storage_retrieval_systems_ASRS.htm

Material Handling Equipment(MHE)There are various kinds of handling equipment in today market; all of it has its own unique performance. They can be classified into five major categories.

Transport Equipment - Used to move material from one location to another (e.g., between workplaces, between a loading dock and a storage area, etc.)

Positioning Equipment - Used to handle material at single location so that it is in the correct position for subsequent handling, machining, transport, or storage.

Unit Load Formation Equipment - Used to restrict materials so that they maintain their integrity when handled a single load during transport and for storage.

Storage Equipment - Used for holding or buffering materials over a period of time.

Identification and Control Equipment - Used to collect and communicate information that is used to coordinate the flow of materials within a facility, between facility and its suppliers and customers. The identification of materials and associated control can be performed manually with no specialized equipment.

We will place our focus on Transport Equipment as these are the ones used most frequently in the warehouse.

-7:12 PM-

Thursday, January 04, 2007

Chapter 3

The 6 apprentices gathered at L.O.M Ancient Inn, attempting to decode clue 1. After spending 3 days and nights of deciphering, they finally unrevealed the mystery of the first clue - The glorious Internet!!

And here forth, they embarked on an eNchaNtiNg and ePic journey to search for the elusive internet....

Feeling Weary and Exhausted, the 6 apprentices on the verge of giving up. Before long, they stumbled upon a pile of ruins... the characters on the stones are similar to the clue...!!! A glimpse of HOPE spark off!! Upon their eyes, it's the very Internet itself! *Fast Forward***>>>>>>>

Part of the secret Manual shall reveal in the next posts. TO BE CONTINUED~~

-11:49 PM-

Chapter 2After learning what MJT says, they found out that there are 3 pieces to the secret manual located at 3 unknown foreign lands.

1st Clue - On a line where information flows

2nd Clue - Fortress for knowledge dwellers

3rd Clue - Find the legendary MGHK(yet another secret character)

Upon bestowed the 3 clues, the 6 apprenctices shall journey forward to quench their thirst for DCM knowledge.....

-11:21 PM-

Chapter 1One Fine Day, 6 individual apprentices come together to form a group under the influence of DCM. Under the teachings of MJT (secret character)for few weeks, the 6 apprentices came to know of a secret manual and immersed themselves to find it. MJT got hold of the news that these 6 apprentices were desperate to gain the knowledge of the secret manual thus he decided to tell them everything he knows....

-9:18 PM-

Unit Load AS/RS

Unit Load AS/RS

Deep-Lane AS/RS

Deep-Lane AS/RS gy gradually allows storage and picking of inventory to be increasingly streamlined and efficient, resulting in overall lower operational cost and increased performance.

gy gradually allows storage and picking of inventory to be increasingly streamlined and efficient, resulting in overall lower operational cost and increased performance.  Next in line would be the cart, though not entirely an advance version of the MHE, though maybe not even a MHE itself, undoubtedly its basic functionality remains the same, as mention in http://en.wikipedia.org/wiki/Cart , “Carts have many different shapes but the basic idea of transporting material (or maintaining a collection of materials in a portable fashion) remains.”

Next in line would be the cart, though not entirely an advance version of the MHE, though maybe not even a MHE itself, undoubtedly its basic functionality remains the same, as mention in http://en.wikipedia.org/wiki/Cart , “Carts have many different shapes but the basic idea of transporting material (or maintaining a collection of materials in a portable fashion) remains.”

The Forklift!

The Forklift!